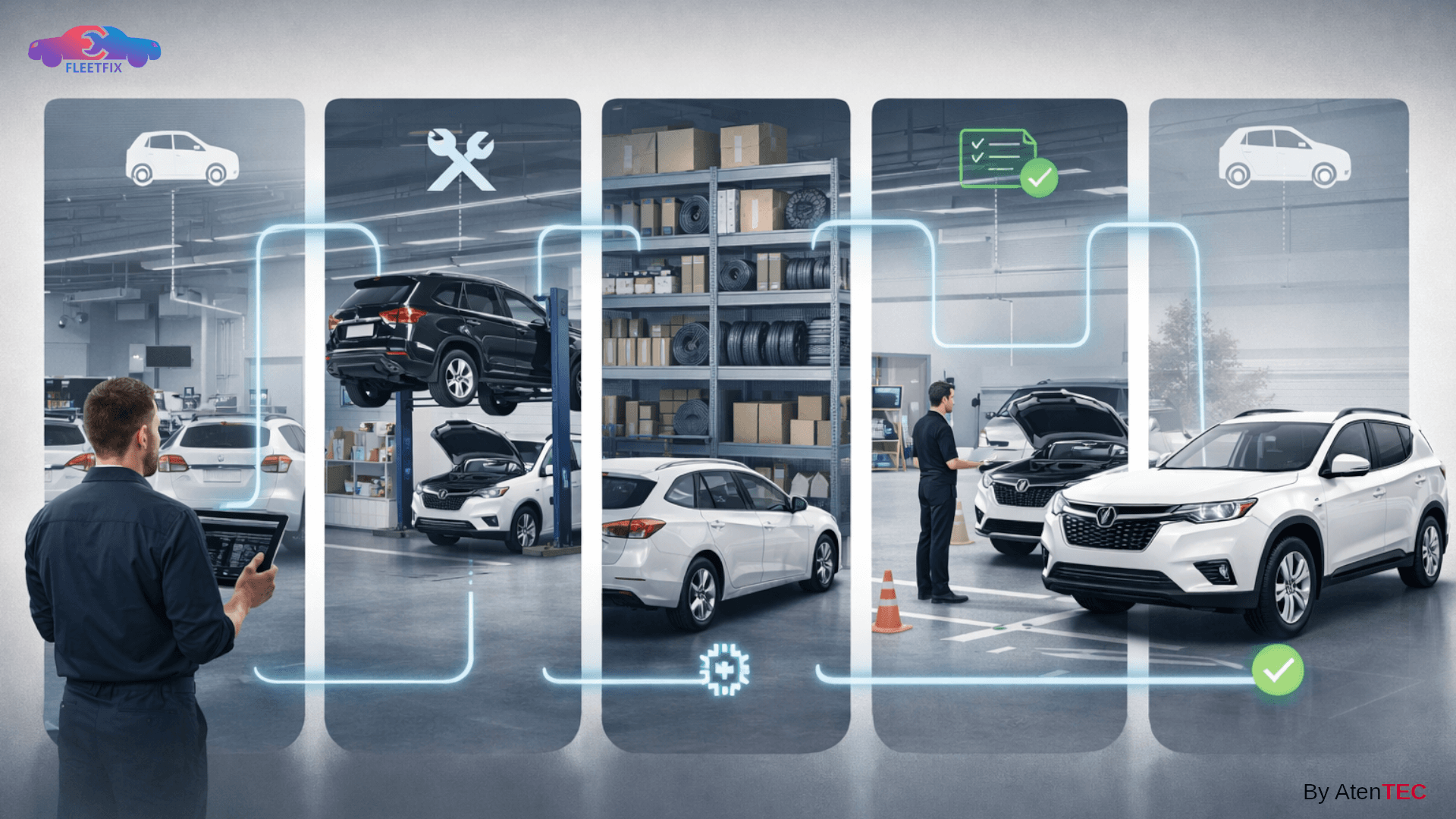

The Modern Vehicle Maintenance Workflow for Rental Companies: How Digital Fleet Repair Cycles Reduce Downtime (Pending)

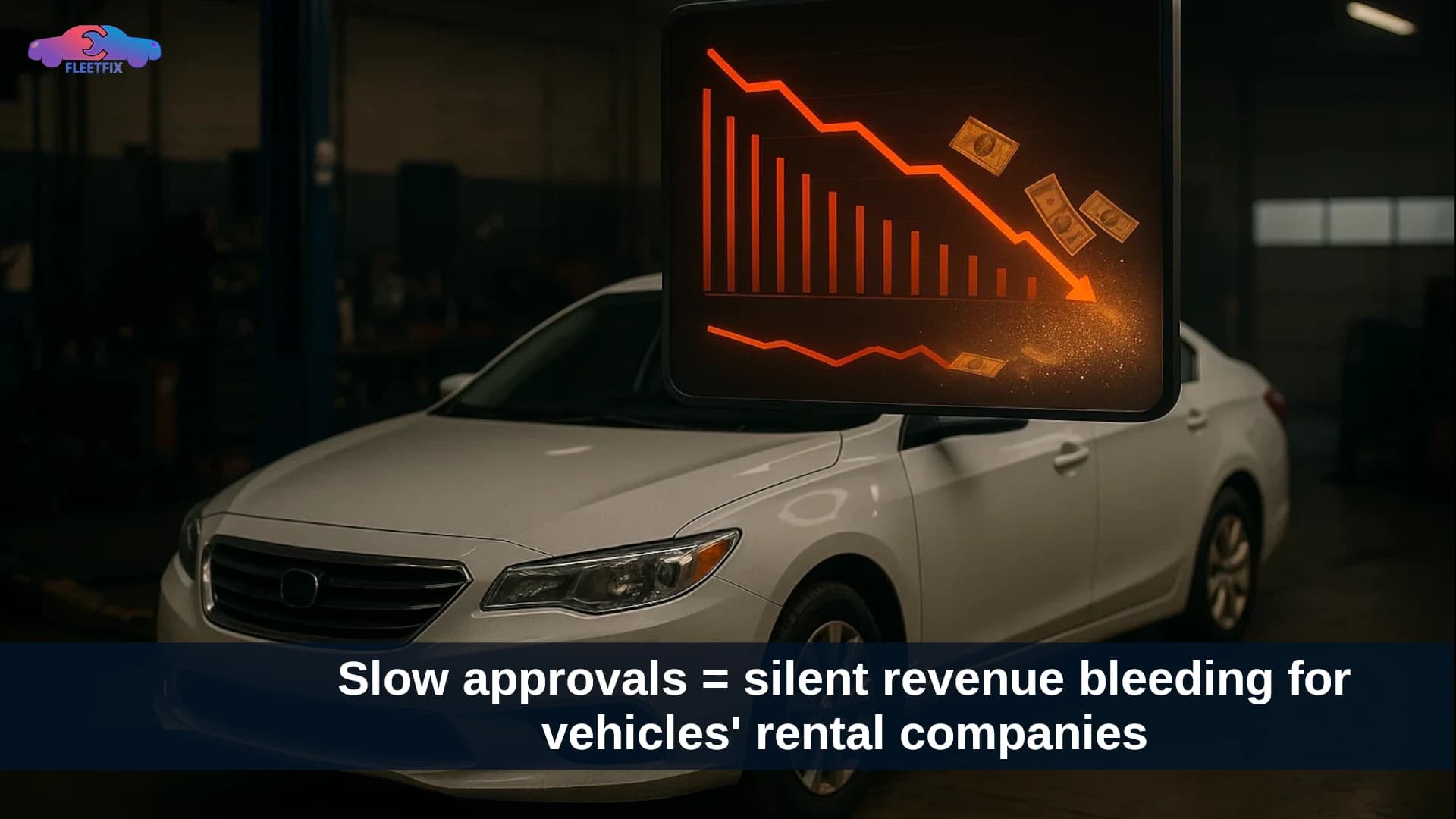

Vehicle maintenance is one of the largest hidden cost centers in car rental and fleet leasing companies. While repairs themselves are unavoidable, vehicle downtime (Pending), poor workshop coordination, and manual maintenance workflows quietly erode utilization rates and profitability.

For many rental companies, the real problem is not how vehicles are repaired—but how repairs are managed.

This article explores a modern, end-to-end fleet maintenance workflow designed specifically for rental fleets, leasing companies, and multi-branch fleet operations. It breaks down the digital repair cycle that eliminates idle time, improves workshop productivity, and returns vehicles to service faster.

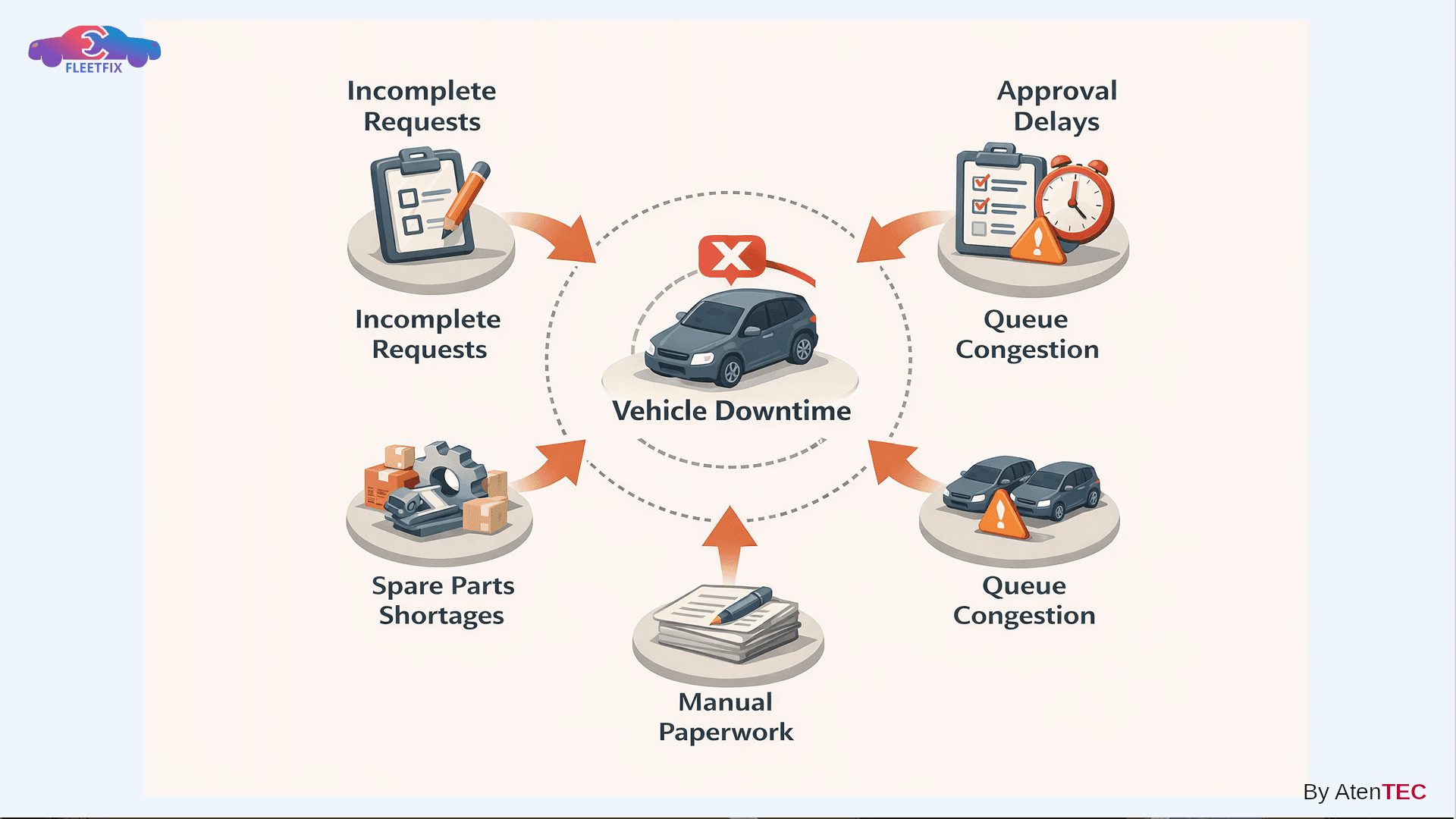

Why Vehicle Downtime (Pending) Is the Biggest Risk in Rental Fleet Maintenance

In traditional car rental maintenance operations, vehicles often sit idle due to:

- Incomplete repair requests

- Delayed approvals and documentation checks

- Poor workshop queue visibility

- Spare parts shortages

- Manual job cards and paper-based processes

These gaps create what operations teams call pending time—periods where a vehicle is neither generating revenue nor actively being repaired.

Modern fleet maintenance software focuses on eliminating this pending time by digitizing and connecting every step of the repair lifecycle.

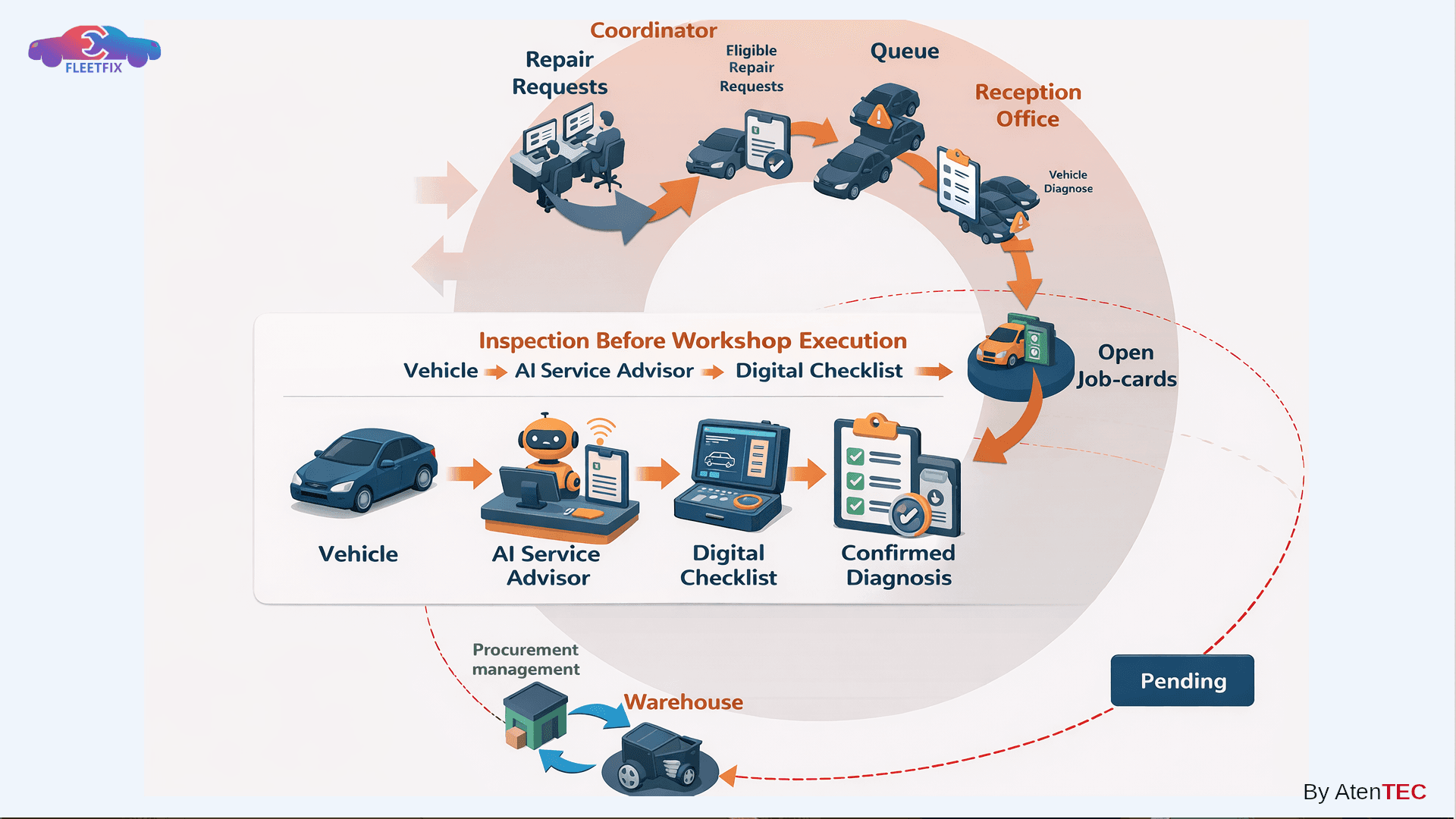

Step 1: Digital Repair Requests for Rental Fleets

The maintenance cycle begins when a rental, lease, or corporate vehicle requires service. In many companies, repair requests still arrive via phone calls, emails, or WhatsApp messages, leading to missing details and repeated follow-ups.

A modern digital maintenance intake system standardizes this process by requiring:

- Vehicle details and mileage

- Clear problem descriptions

- Mandatory photos or videos

This ensures that workshop teams receive accurate information from the start, reducing diagnostic delays and repeat inspections.

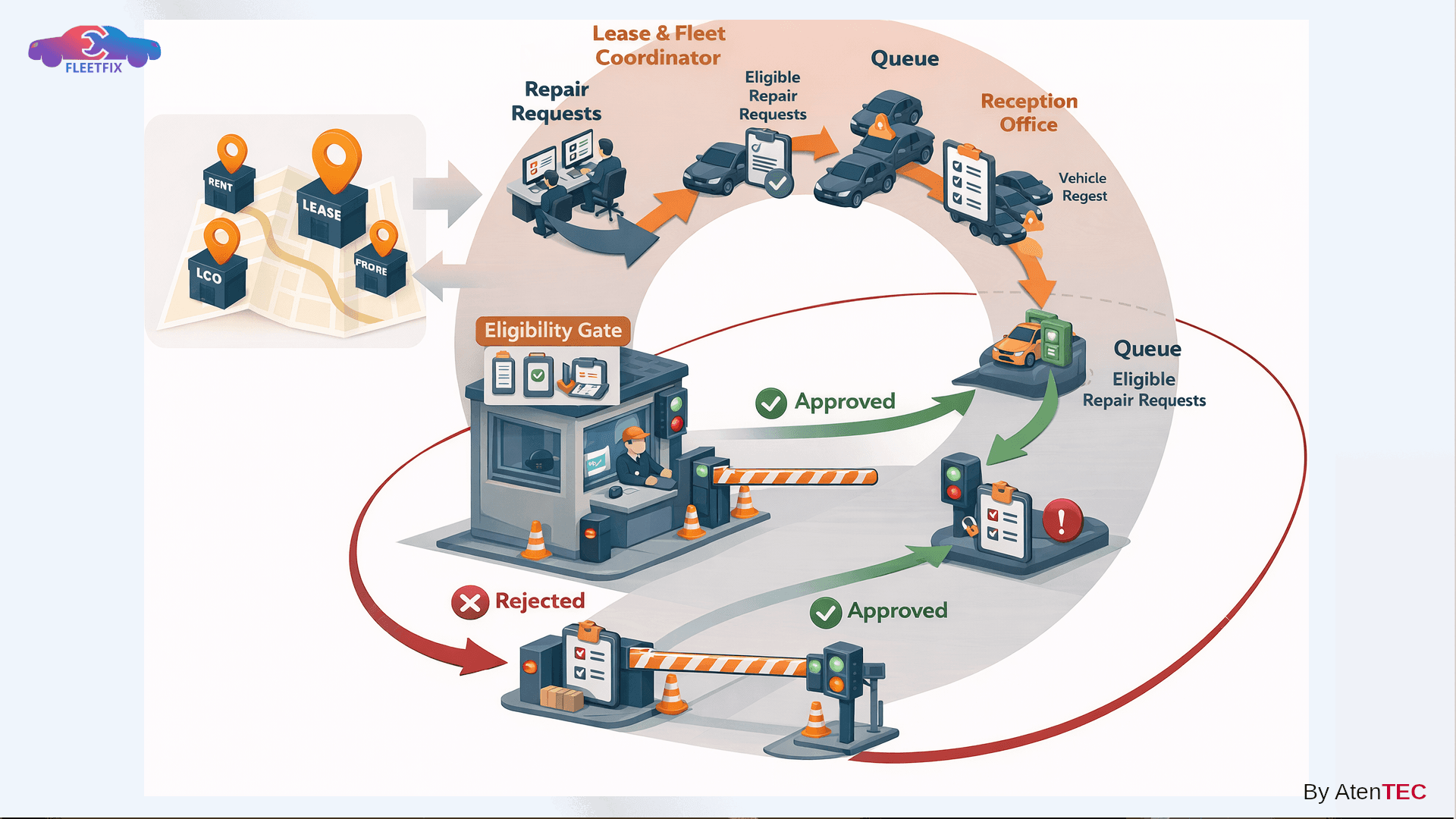

Step 2: Fleet Eligibility and Contract Validation

Before a vehicle enters the workshop queue, fleet coordinators must confirm that:

- Insurance and permits are valid

- The repair is authorized under the rental or lease contract

- Internal company policies are met

This eligibility gate prevents unauthorized vehicles from consuming workshop capacity—one of the most common causes of congestion in rental fleet workshops.

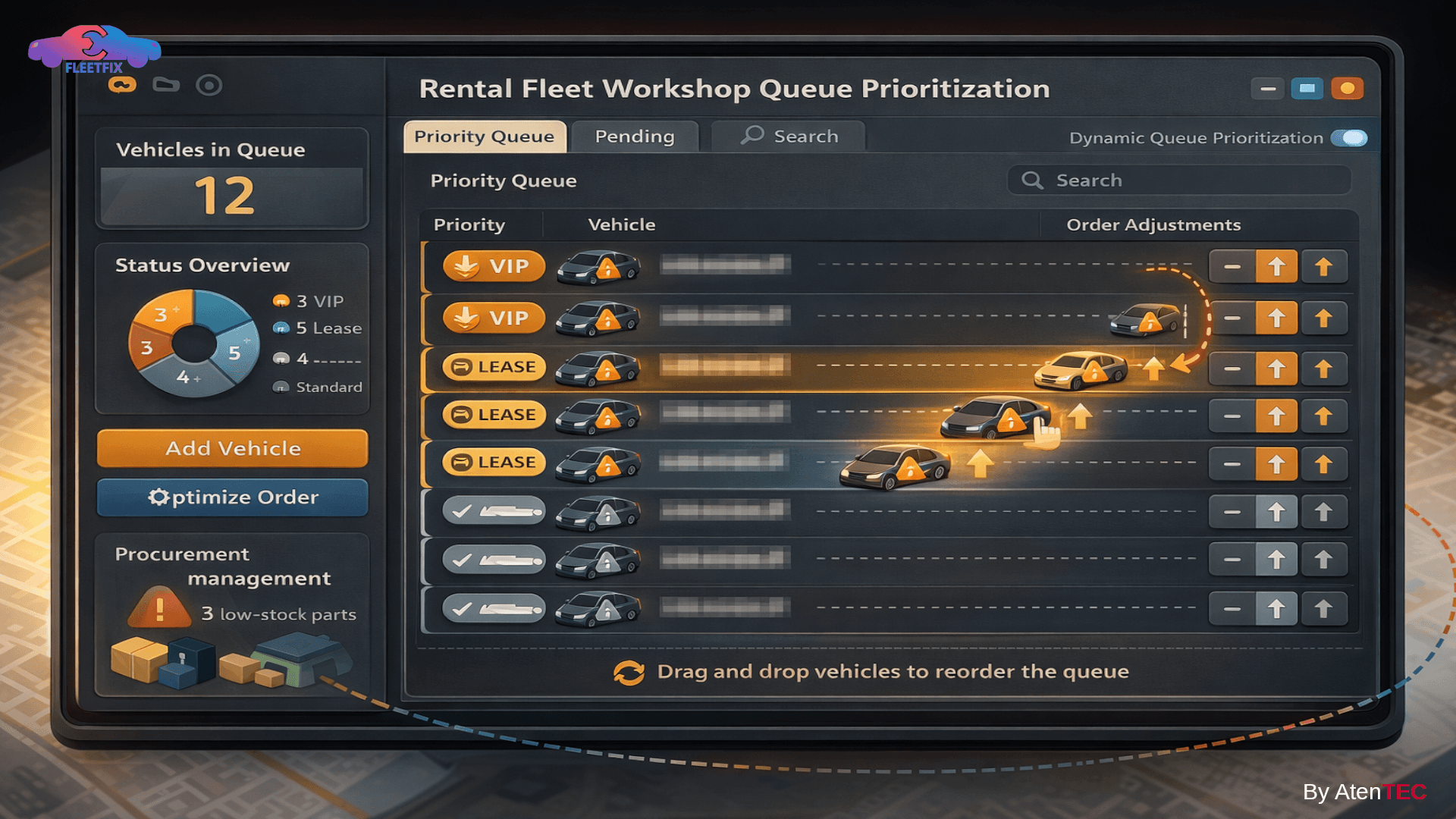

Step 3: Workshop Queue Management for Rental Companies

Once approved, the vehicle enters a digital workshop queue. Unlike traditional first-come, first-served systems, modern fleet platforms should allow prioritization based on:

- High-value rental contracts

- VIP or long-term lease vehicles

- Seasonal demand peaks

Real-time queue visibility allows operations managers to make informed decisions that directly impact fleet availability.

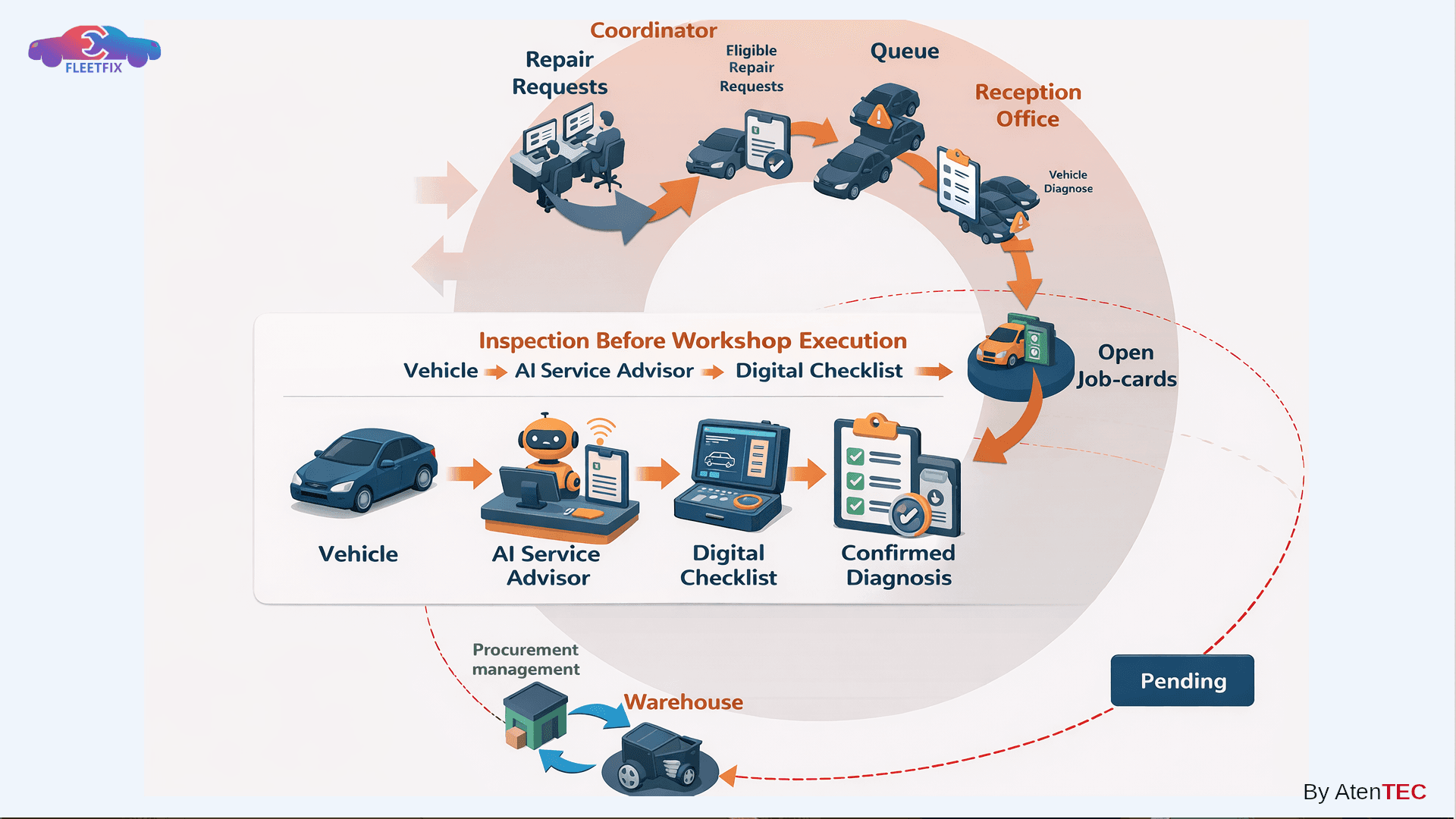

Step 4: Standardized Vehicle Diagnosis

A structured vehicle diagnosis is performed by a service advisor before work reaches the workshop floor. Using mobile tools, advisors:

- Select symptoms from standardized lists

- Capture inspection photos

- Reference historical maintenance data

This reduces misdiagnosis, unnecessary labor, and incorrect spare parts ordering—major cost drivers in rental fleet maintenance.

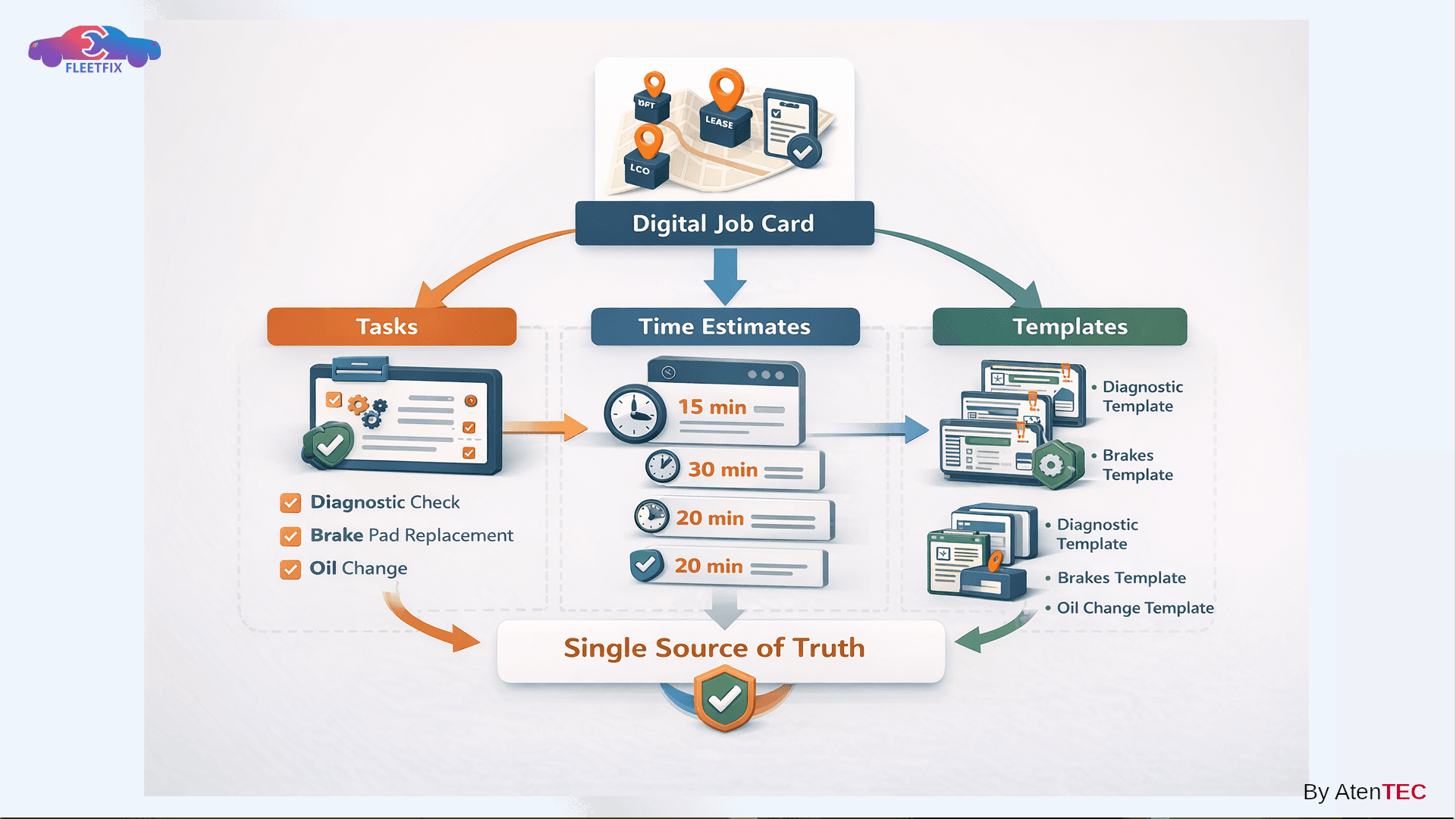

Step 5: Job Cards and Repair Planning

Once diagnosis is complete, a digital job card is created. This becomes the single source of truth for the repair.

Repair plans are broken down into:

- Defined tasks

- Standard labor times

- Repeatable repair templates for common issues

This level of structure is essential for workshop productivity, cost control, and accurate turnaround time forecasting.

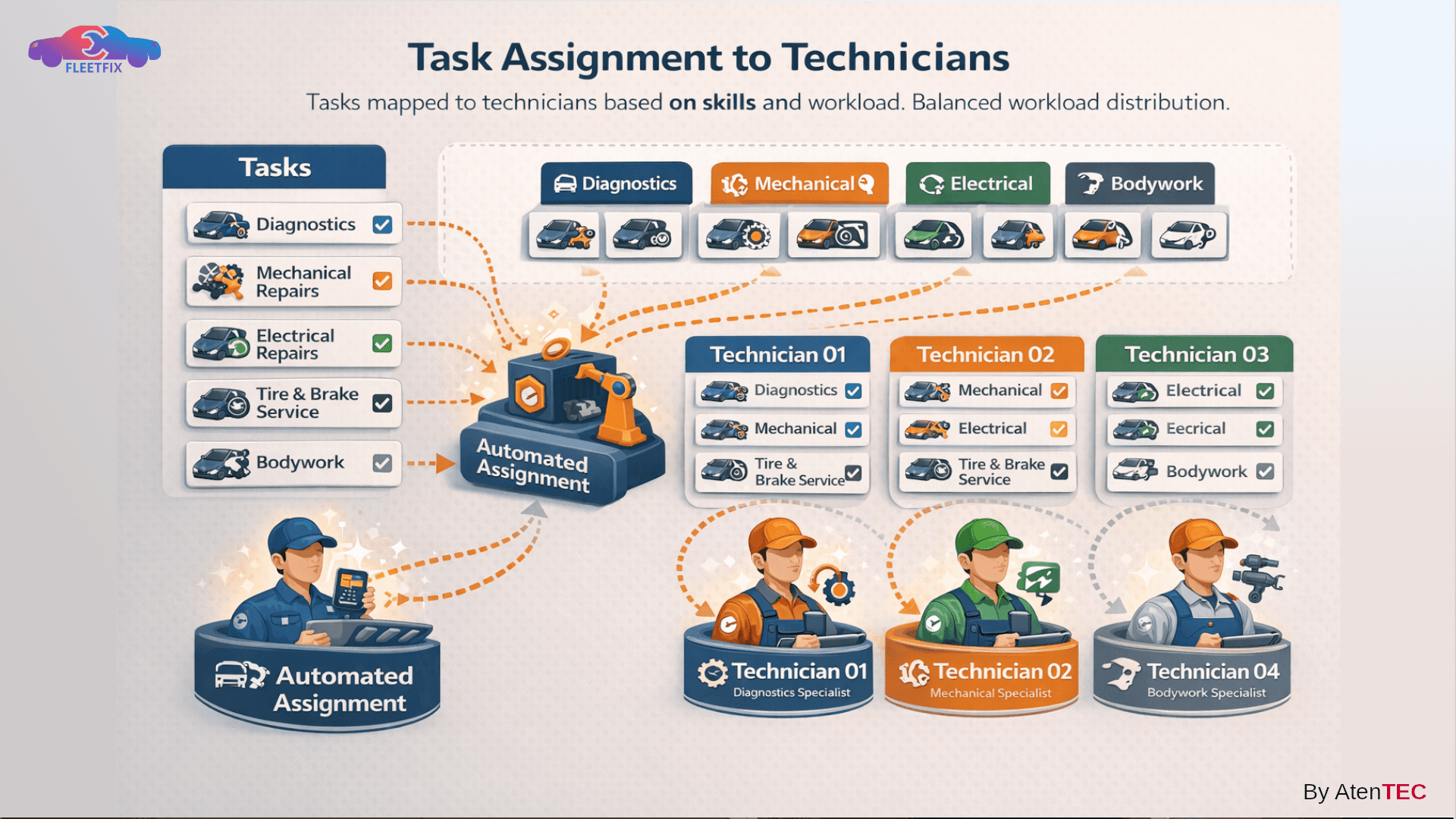

Step 6: Technician Assignment and Workforce Optimization

Assigning the right technician to the right task is critical in high-volume rental workshops. Smart workforce allocation considers:

- Technician skill sets (mechanical, electrical, bodywork)

- Current workload

- Task complexity

This prevents bottlenecks, improves labor efficiency, and reduces overtime costs.

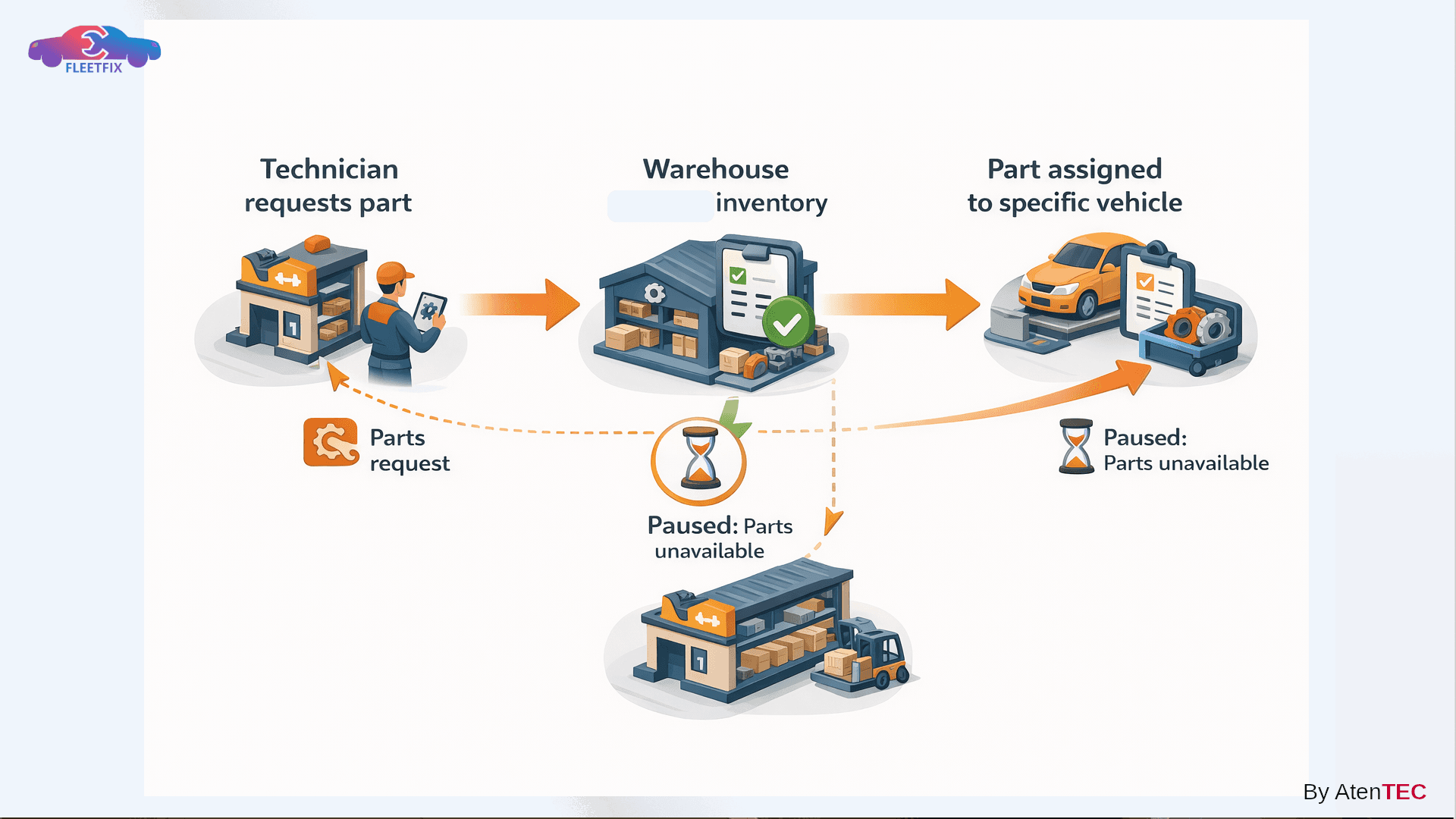

Step 7: Spare Parts Management and Warehouse Integration

Spare parts availability is one of the top causes of delayed vehicle repairs. Modern fleet maintenance systems should integrate workshops directly with warehouse operations.

Key capabilities include:

- Digital spare parts requests

- Smart Inventory management

- Automatic labor time pausing when parts are unavailable

This ensures accurate productivity metrics and eliminates parts misuse across multiple repairs.

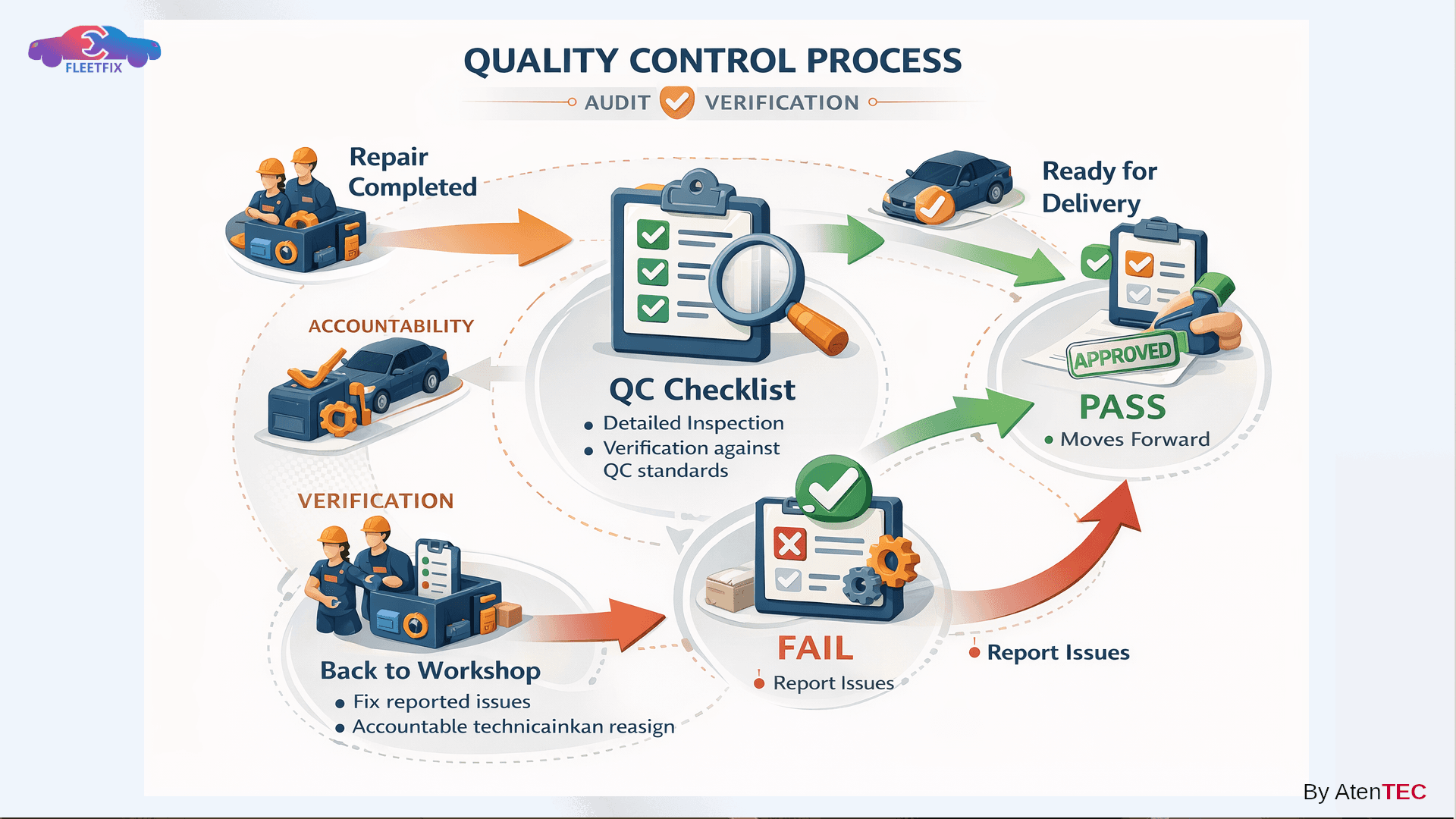

Step 8: Quality Control and Road Testing

Before a vehicle returns to service, it must pass quality control. Digital QC checklists require:

- Task verification

- Photo evidence

- Road test confirmation

If issues are detected, the vehicle could re-enters the repair workflow without manual paperwork or confusion.

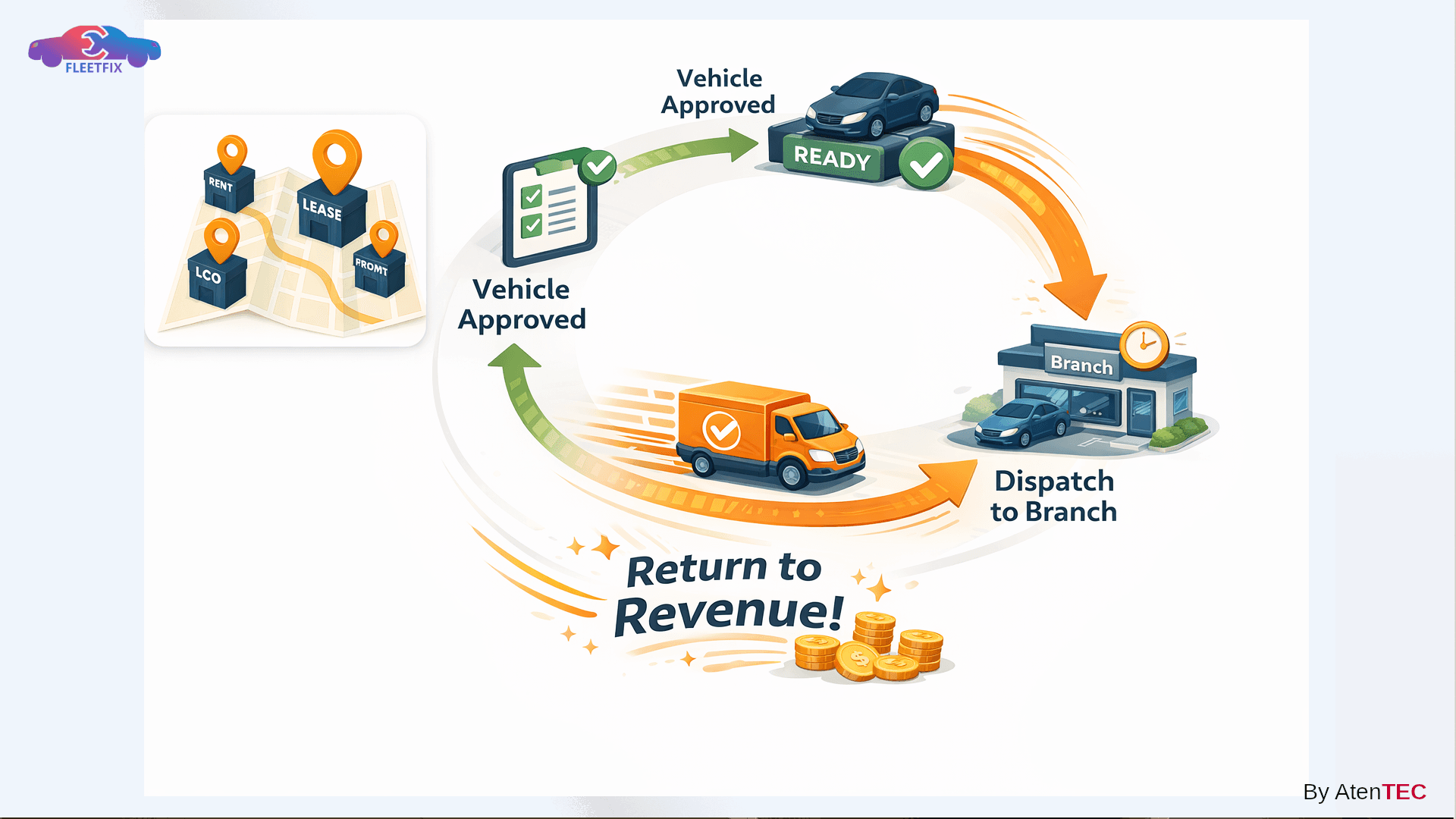

Step 9: Ready-to-Rent Vehicles and Fleet Dispatch

Once approved, the vehicle is marked as ready for rent or lease. Automatic notifications inform branches and fleet coordinators, and driver dispatch can be scheduled if relocation is required.

This final step ensures vehicles return to revenue-generating status as quickly as possible.

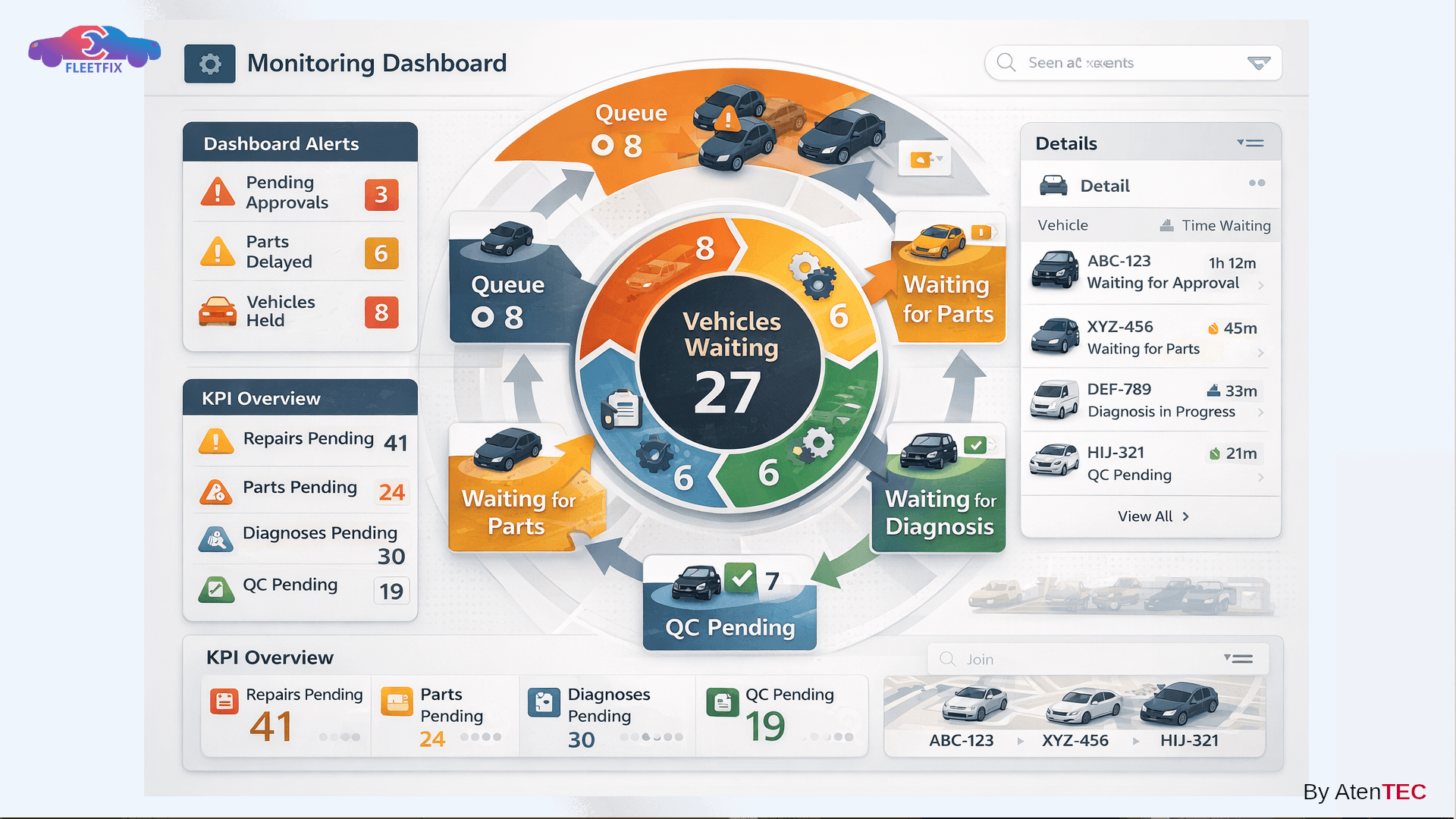

Continuous Monitoring of Fleet Maintenance Bottlenecks

Throughout the entire repair lifecycle, modern fleet systems should track where vehicles are waiting:

- Awaiting approval

- Waiting for spare parts

- Queued for diagnosis

- Pending quality control

Dashboards provide management with real-time insights into fleet maintenance KPIs, enabling proactive decision-making rather than reactive firefighting.

Final Thoughts: The Future of Vehicle Maintenance in Rental Fleets

As rental fleets scale and customer expectations rise, manual maintenance processes are no longer sustainable. Companies that invest in digital fleet maintenance workflows who used FleetFix gain measurable advantages in:

- Vehicle availability

- Workshop efficiency

- Cost control

- Customer satisfaction

If you are interested in understanding how a structured repair cycle applies to your rental or leasing operations, you can book a session to explore the FleetFix workflow in detail and identify opportunities to reduce downtime (Pending) across your fleet.